Wire cleaners and wire rope lubricators are indispensable in the world of repair for cables, where accuracy is essential. These cutting-edge devices have a crucial role to play in ensuring smooth operation and long-lasting life of cables from various industries. Cleaners for ropes and ropes are vital for the maintenance of cables. In this article we discuss their purposes, benefits and the transformative impact on the overall effectiveness. For more information, click Cable Cleaner

Understanding wire Rope Lubricators

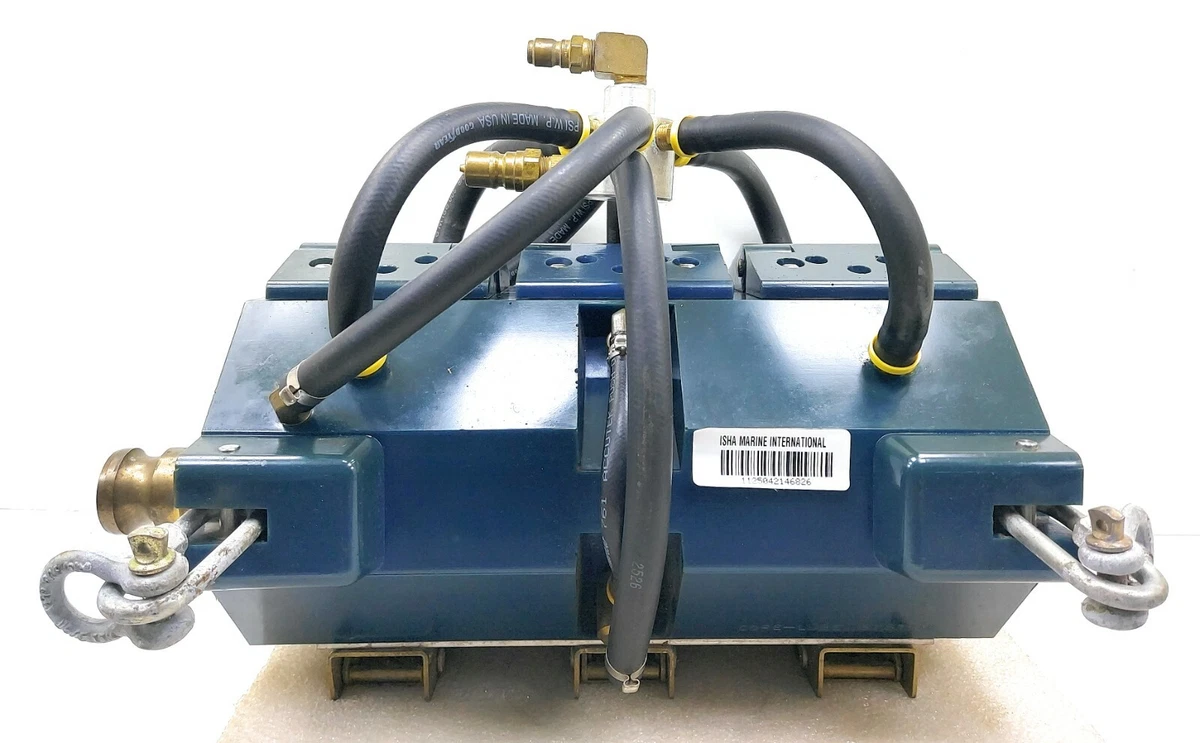

Wire Rope Lubricators are machines that allow you to lubricate wire ropes in a systematic method. This is an essential step to stop friction and corrosion while increasing the durability of the cable. The lubricator distributes lubricant evenly across the length and length of the wire rope in order to protect it from wear.

The role of wire cleaners in Cable Maintenance:

Cleaning wires and cable cleaners are both vital to ensure clean cables. They are made to eliminate contaminants, debris and fluids that could build up on cables during various processes. Wire cleaners are vital in harsh environments, where cables can be subjected to extreme conditions. They are designed to ensure maximum performance and prevent potential damage to the cable.

Optimizing Cable Lifespan:

Combining wire cleaners and the lubrication of wire rope can prolong the length of a cable. Utilizing wire rope cleaners to remove contaminants and applying the lubrication process, cables are shielded from damaging effects like corrosion, friction or external elements. The protection of the integrity of the cable translates into prolonged operational efficiency and lower costs for maintenance in the long run.

Efficiency in application:

Wire rope lubricators were designed to be easy to use and efficient in application. The lubricators are able to be used on a variety of sizes and types of wire ropes. This allows for versatility in the cable maintenance. Systematic and automated lubrication eliminates the risk of uneven applications that manual techniques can cause.

Ability to Adapt in a Changing Environment:

Lubricators for wire ropes, and wire cleaners, are especially important in industries where cables must endure harsh conditions, like the ones used in drilling, construction or maritime operations. They are specifically designed to stand up to harsh environments that makes them reliable instruments for cable maintenance in diverse conditions.

Cost-Effective Maintenance Solutions:

A proactive approach to maintaining your cable using cables and lubricants, as well as cleaners can be a cost-effective choice in the long-term. The initial investment in these tools is not that significant compared to future costs, such as repairs and replacements of cables because of poor maintenance.

Conclusion:

Lubricators and wire cleaners for wire ropes are the guardians who guarantee the integrity of cables and precision across a wide range of industries. The systematic lubrication and cleaning of contaminants can reduce the cost of maintenance and enhances operational efficiency. Cables are still in use in the most critical sectors, therefore using cable maintenance tools that can be used to ensure reliability and efficiency is essential.